Mar 2020 - Nov 2021

Humanoid Robot Avatar

Project Overview

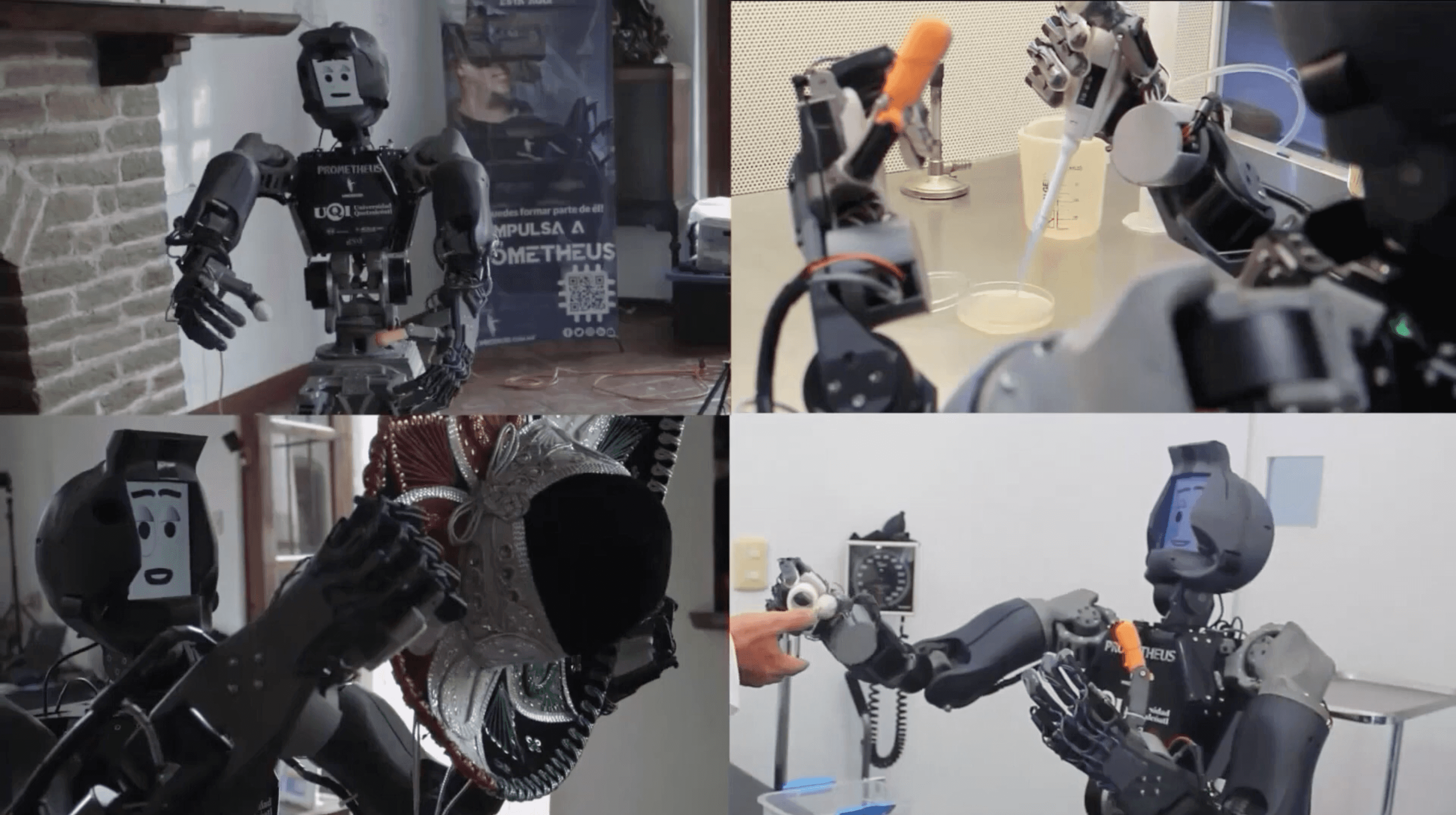

Mexico's first anthropomorphic robot avatar was developed as a pioneering entry into the ANA Avatar XPRIZE competition. Equipped with the ability to hear, see, feel, and speak, our robot avatar sets new standards in robotic telepresence.

It is designed to mimic human movements in real time, offering a seamless extension of the user's capabilities into remote or hazardous environments. With 39 degrees of freedom and an omnidirectional platform, the robot demonstrates extraordinary agility and precision in object manipulation and environmental interaction.

The motivation behind this project was driven by a vision to transcend physical limitations and geographic barriers, enhancing human interaction and operational capabilities through advanced robotic technology. Our team aimed to showcase the potential of teleoperated systems in performing complex tasks with human-like dexterity and sensory perception.

Photo source: YouTube

Responsibilities

As the mechanical design engineer, I was in charge of a variety of activities focusing on all mechanical aspects from the project's inception to its full operation. Here is an overview of some of the responsibilities and activities that I handled during this project:

Planning and Decision-Making: Defined objectives and devised a comprehensive action plan covering all mechanical components. Contributed innovative ideas across various domains, including electronics, control systems, and functional behavior of the robot.

Research and Development: Leading research in mechanical design, structural analysis, material and actuator selection for anthropomorphic humanoid robots.

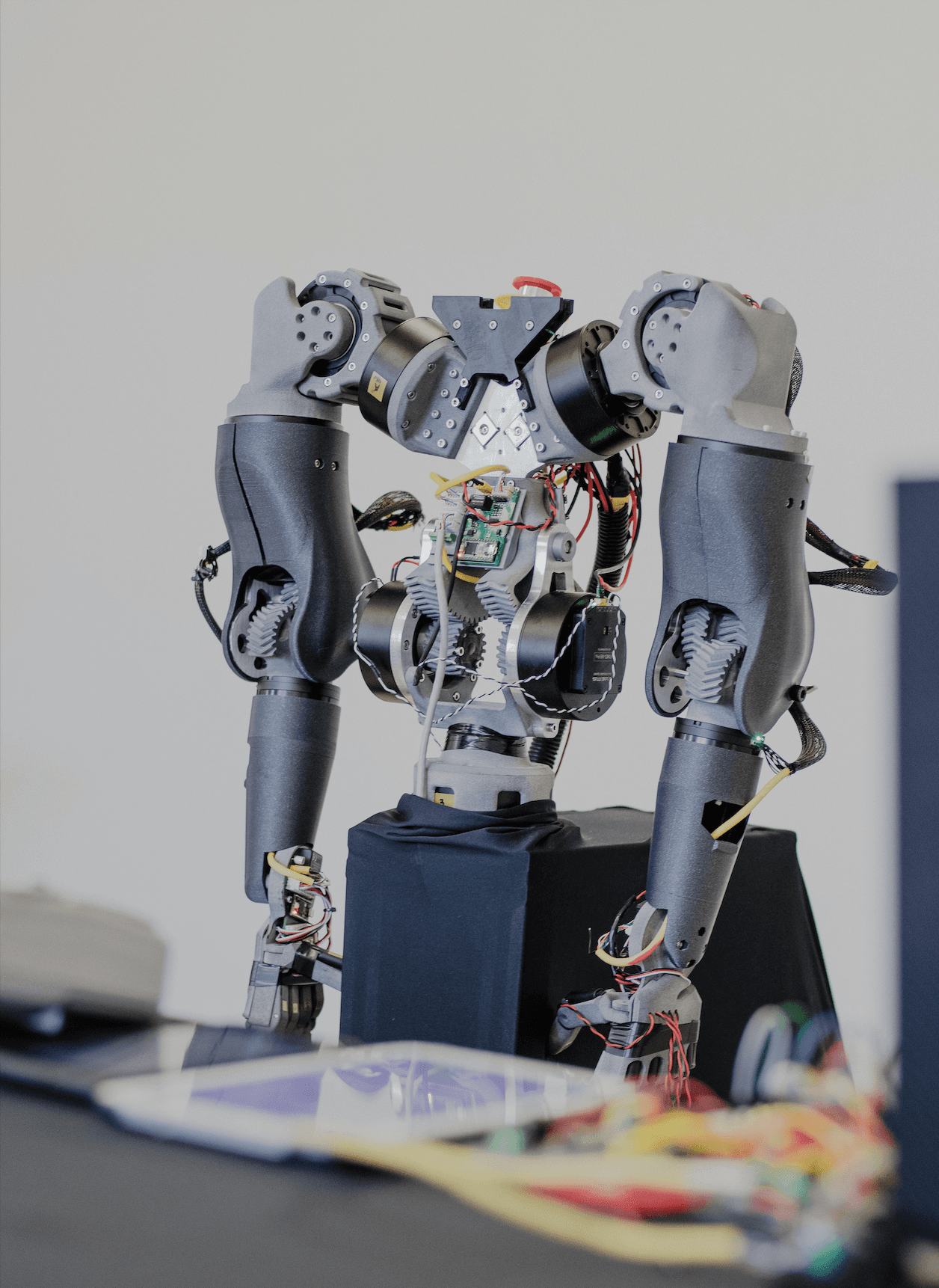

Mechanical Design: Designing the mechanical components of the robot (DFM & DFA), including arms, legs, torso, neck, head, and omnidirectional platform.

Material Selection: Choosing appropriate materials for the specific mechanical constraints.

Actuator Selection: Selecting actuators based on the required specifications for movement and load-bearing capacities.

Finite Element Analysis (FEA): Conducting simulations to assess material properties and forces applied to each component, ensuring design viability under operational stresses.

Manufacturing: Overseeing the manufacturing of specific parts, ensuring designs are optimized for manufacturability.

Assembly: Leading the assembly process, ensuring parts and components tolerances are as designed.

Hands Upgrade: Upgrading the robot's hands with more compliant fingers and integrating sensors into the fingertips to enhance tactile capabilities.

Integration of Hardware: Incorporating sensors, electronic boards, and computing systems into the robot considering harnessing and functional design.

Cross-functional Collaboration: Maintaining constant communication with different teams to ensure the mechanical design supports and integrates with other aspects of the project, including sensor FOV, joint positioning for simplified kinematic calculations, and mechanical data provision for control algorithms.

Challenges and Solutions

Projects of this magnitude invariably present a multitude of challenges across different phases and areas. However, I believe the following two challenges were the most significant, and overcoming them provided me with invaluable learning experiences:

Initiating the Project

Challenge: The primary challenge was determining our starting point. Despite understanding our goals, requirements, and constraints, the real difficulty lay in deciding where to begin and what to develop first. This challenge was magnified by the lack of a pre-existing platform or guideline; we were charting unfamiliar territory, creating everything from the ground up.

Solution: We addressed this challenge by meticulously planning. Over two months, we dedicated ourselves to planning, defining the system, conducting research, and piecing together the project puzzle. This phase involved setting up a timeline and establishing clear goals. Although not everything proceeded as planned, our strategy accounted for deviations, allowing us to adapt and follow through effectively.

Integration

Challenge: Integration proved to be a formidable challenge—melding different technologies, components, and systems that operate on various protocols into a cohesive unit. I refer to this phase as "integration hell," this phase involves the delicate task of ensuring compatibility between mechanical, electronic, and software components.

Solution: Our strategy for overcoming integration obstacles centered on fast problem-solving robust documentation and planing execution. Equally important was the expertise of team members who brought hands-on experience and troubleshooting instincts. This combination of careful planning, and skilled team members was pivotal in navigating the complexities of system integration.

Results and Impact

Outcomes: This project not only stretched my technical capabilities but also demonstrated our ability to innovate under pressure. Developed for a competition, the project's urgency and our national pride as the only Latin American team accelerated our progress. We successfully built the first teleoperated humanoid robot in Mexico's history, achieving rapid development within just 9 months. This quick development cycle propelled us into the semifinals in Miami, where our robot was the youngest contender in the competition. Our performance in the semifinals was outstanding, securing our robot a place in the finals among the top 17 teams from an initial pool of over 80.

Impact: The project had a profound impact beyond the technical achievements. As a pioneering effort in Mexico, it showcased the country's potential in robotics and engineering on an international stage. We brought attention to our region's innovation capabilities. Making it to the finals of such a prestigious competition highlighted our team's dedication, expertise, and the significant potential of teleoperated humanoid robots. This accomplishment not only elevated our team's status but also inspired our community and peers, demonstrating what can be achieved with determination, innovation, and teamwork.

Media source: YouTube

Conclusion

I am very happy and grateful to have worked with my team on this project. It's remarkable to think that we have contributed to history. The technology behind humanoid robots is only going to improve, with an increase in the development of such robots in the coming years. After the competition in 2022, major companies have begun investing in this area. This marks the beginning of a significant era for humanoid robotics.

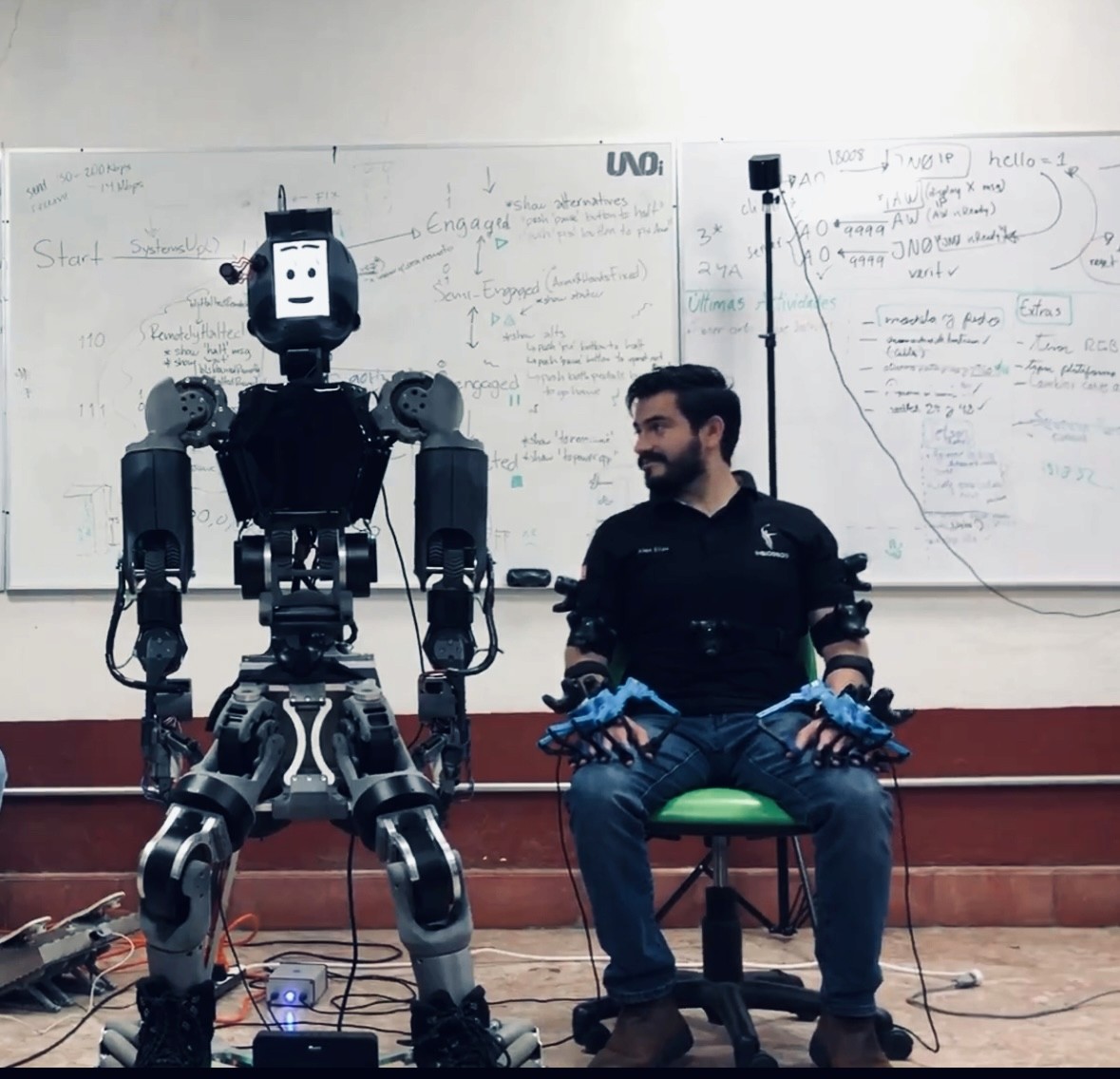

My experience as the first operator of the avatar system was truly unique. It felt as though I was stepping into a different body. When I looked around, it was through the robot's vision, and when I moved my arms and hands, the robot mimicked my movements perfectly. It was a peculiar yet extraordinary experience to control the robot's limbs as if they were my own. This went beyond merely operating a machine; it was an insightful exploration into how humans and robots can interact more closely.