More Projects

This section showcases various projects I’ve developed over the years. As I learn new tools and techniques, I’m motivated to put them into practice. Many of these projects are ongoing, with improvements and updates as I test out new technologies.

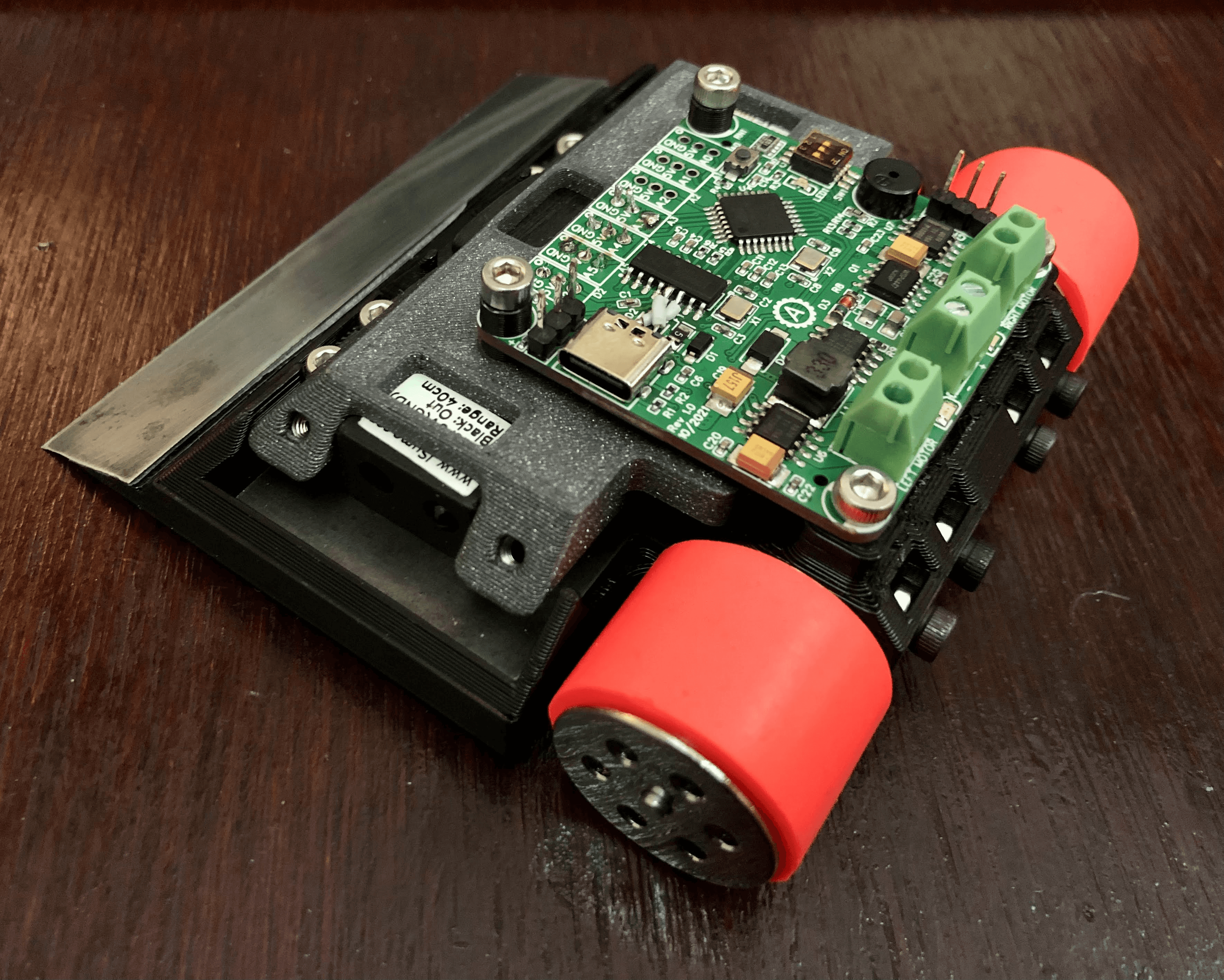

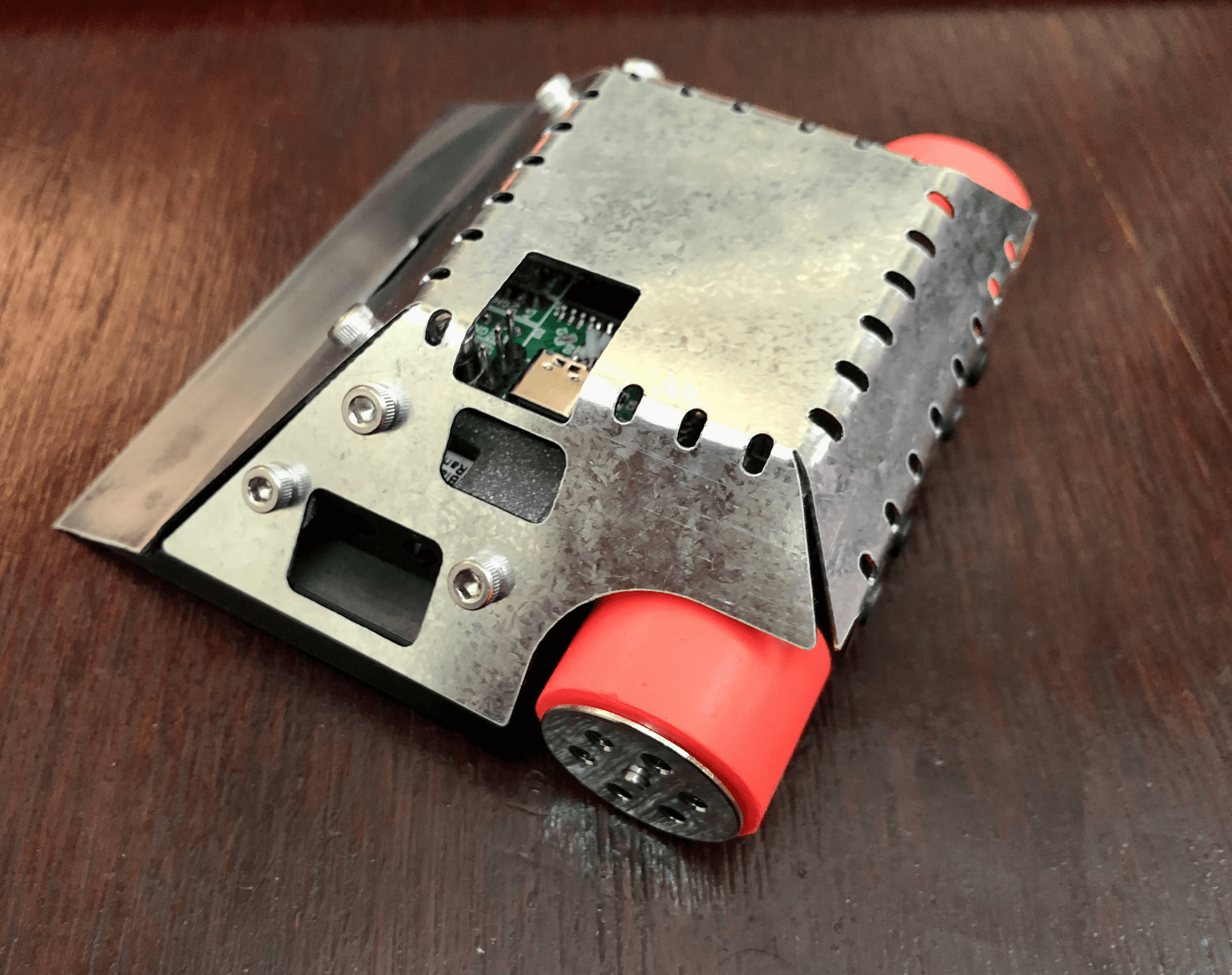

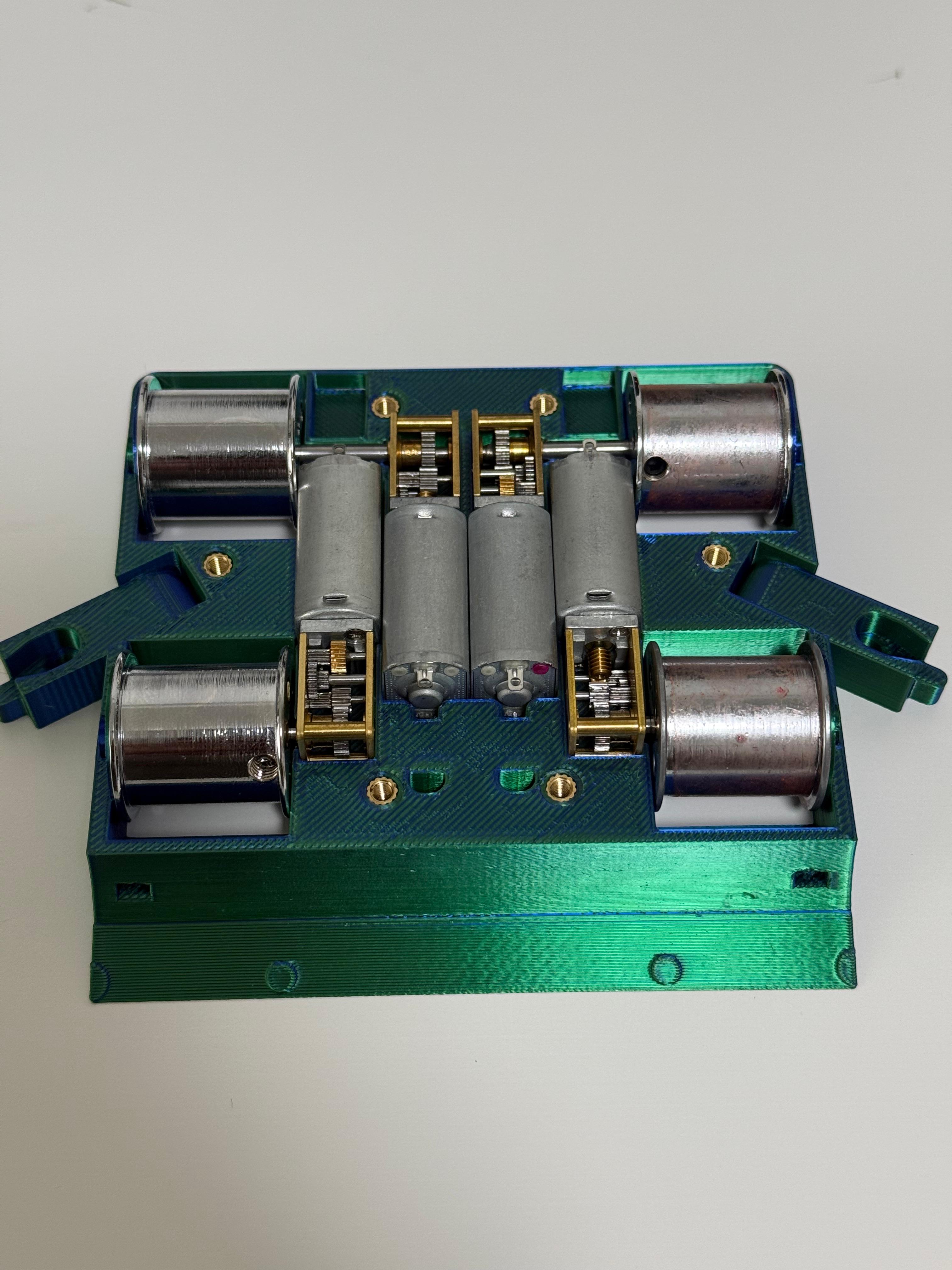

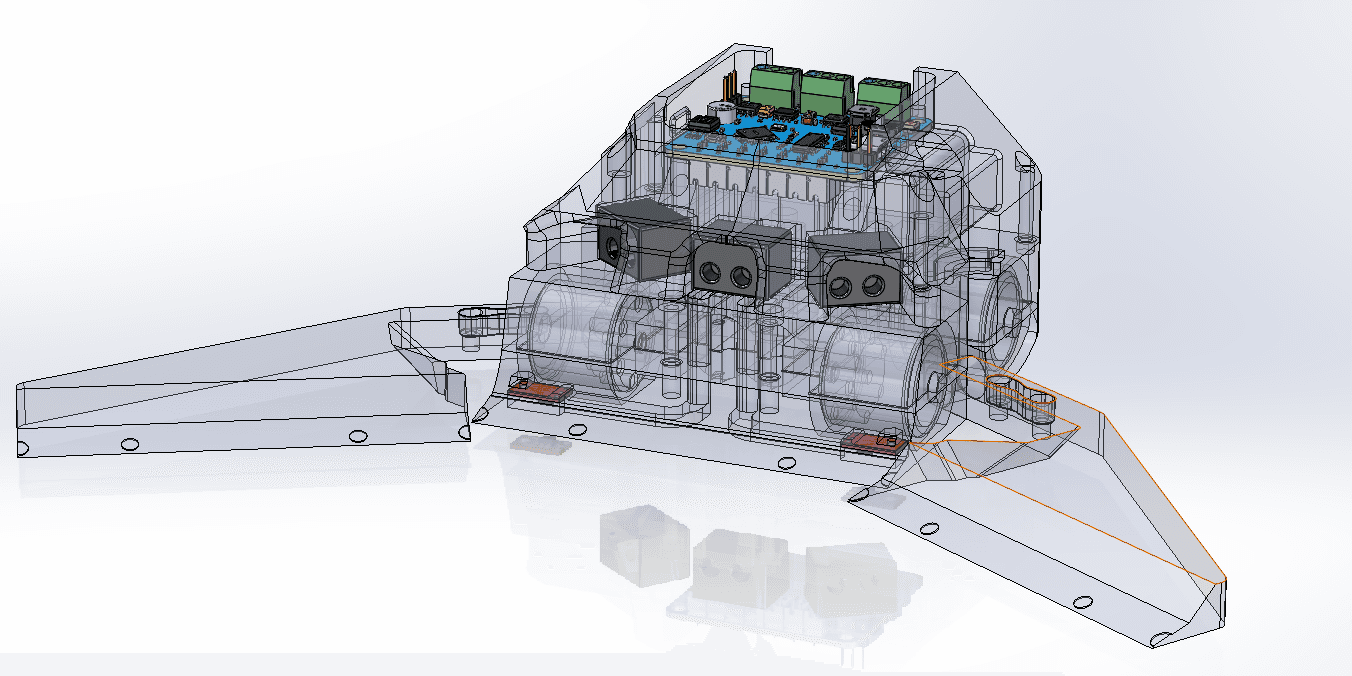

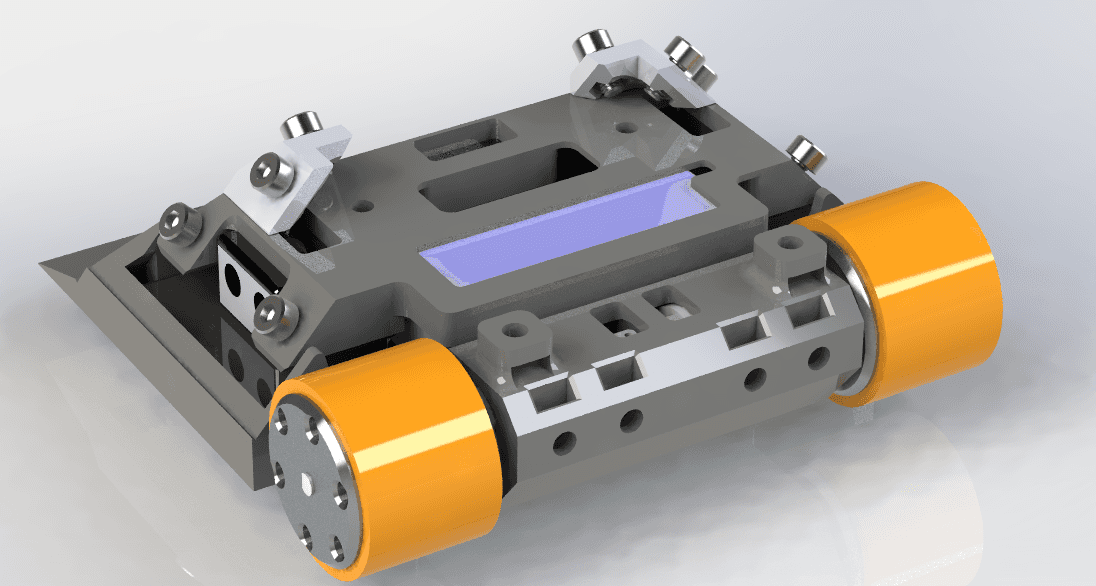

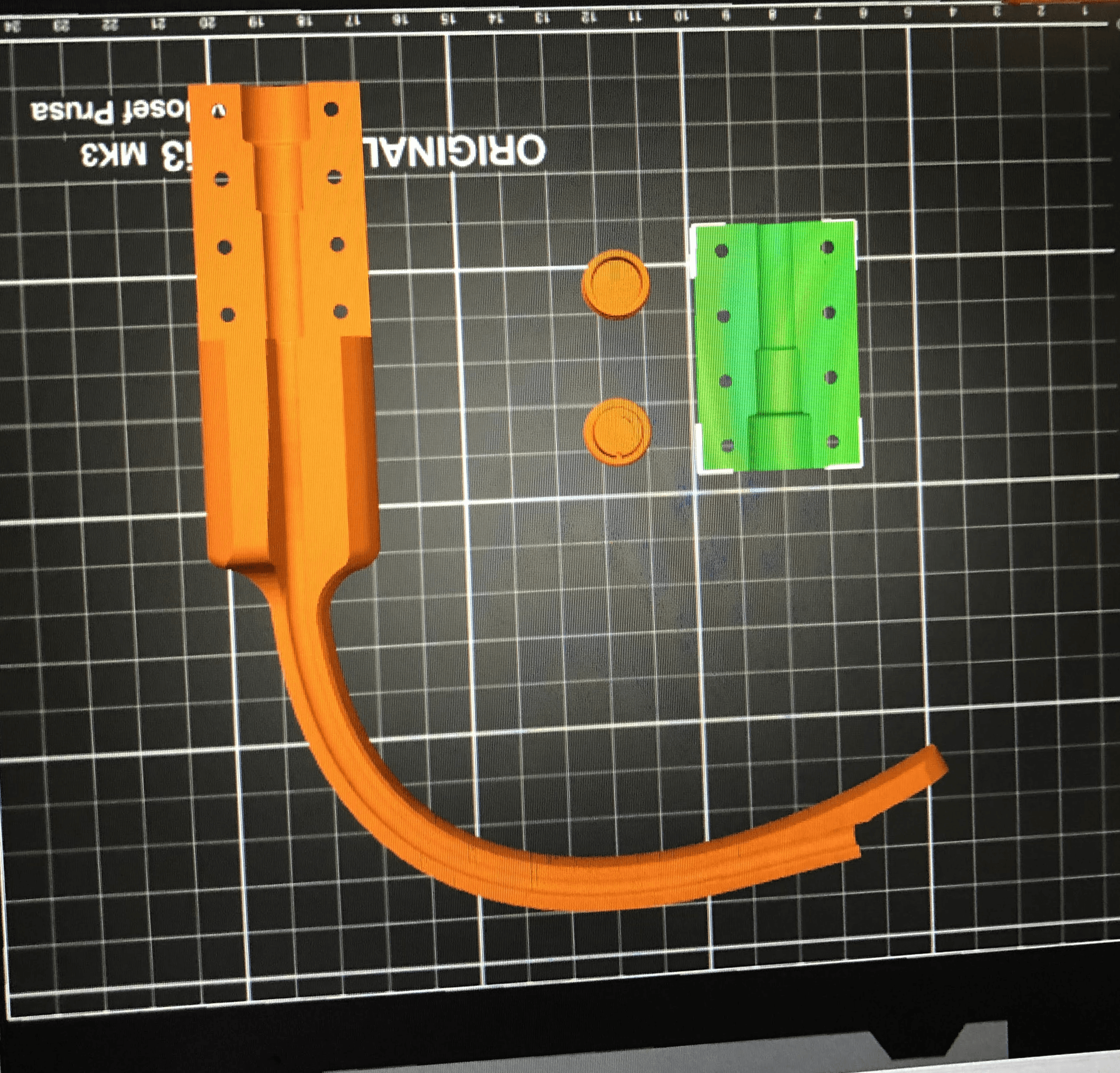

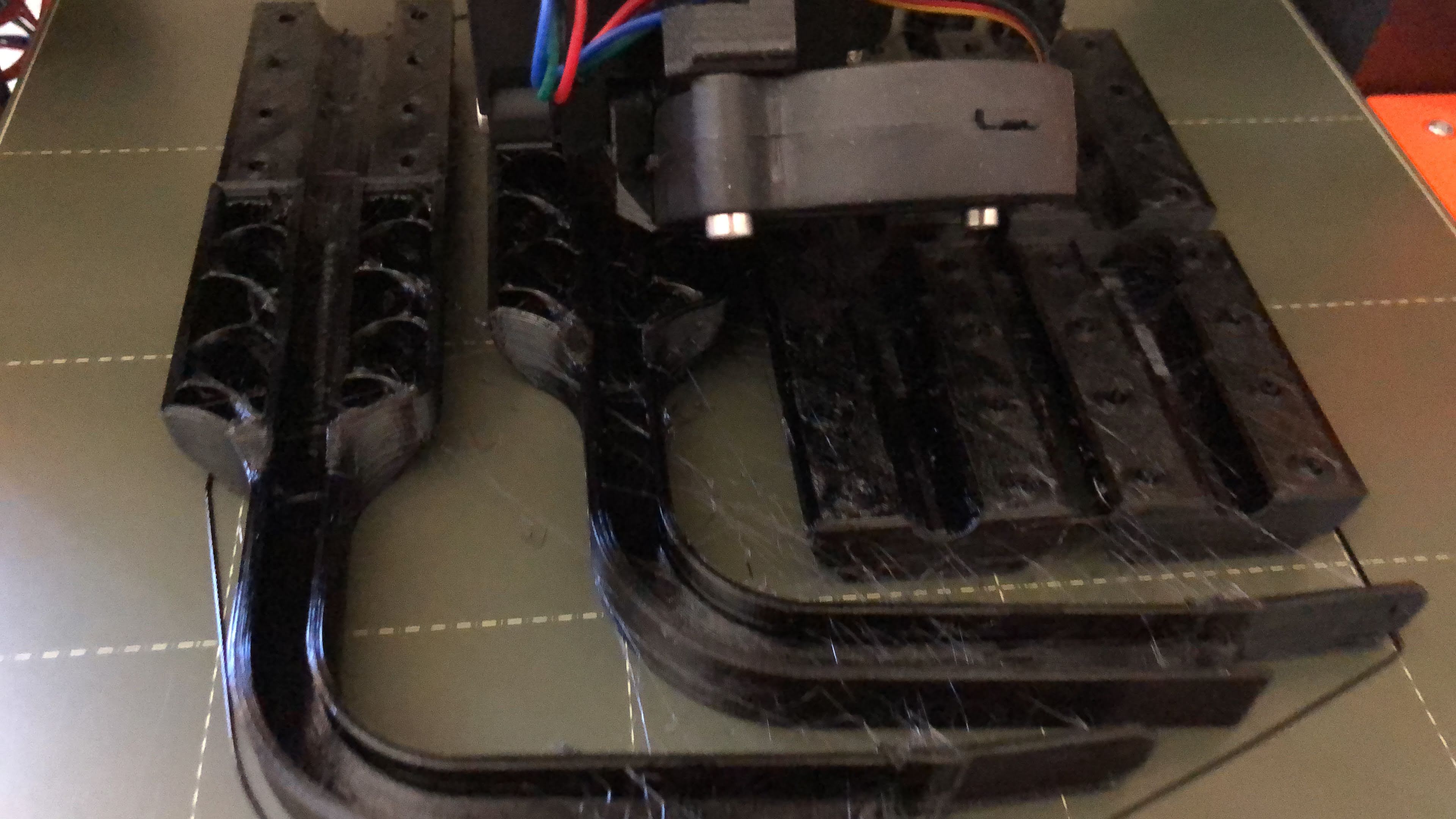

Mini Sumo robot

The Autonomous Mini Sumo project is a compact, versatile version of Robot Sumo, designed within a ten-by-ten-centimeter size and a weight limit of five hundred grams. Equipped with five infrared sensors for opponent detection and line-detection sensors for dojo navigation, this robot focuses on developing strategies and combat algorithms. With minimal rules, this category encourages experimentation with different designs, including various wheel setups, additional sensors, and diverse material choices. This platform allows for testing modular technologies, such as different sensor types—IR, TOF, ultrasonic—and manufacturing techniques, like a 3D-printed stainless steel body or sheet metal construction. Since it requires a combination of mechanical design, electronics, and programming knowledge, fitting everything into a small robot makes it easy to develop new ideas and approaches.

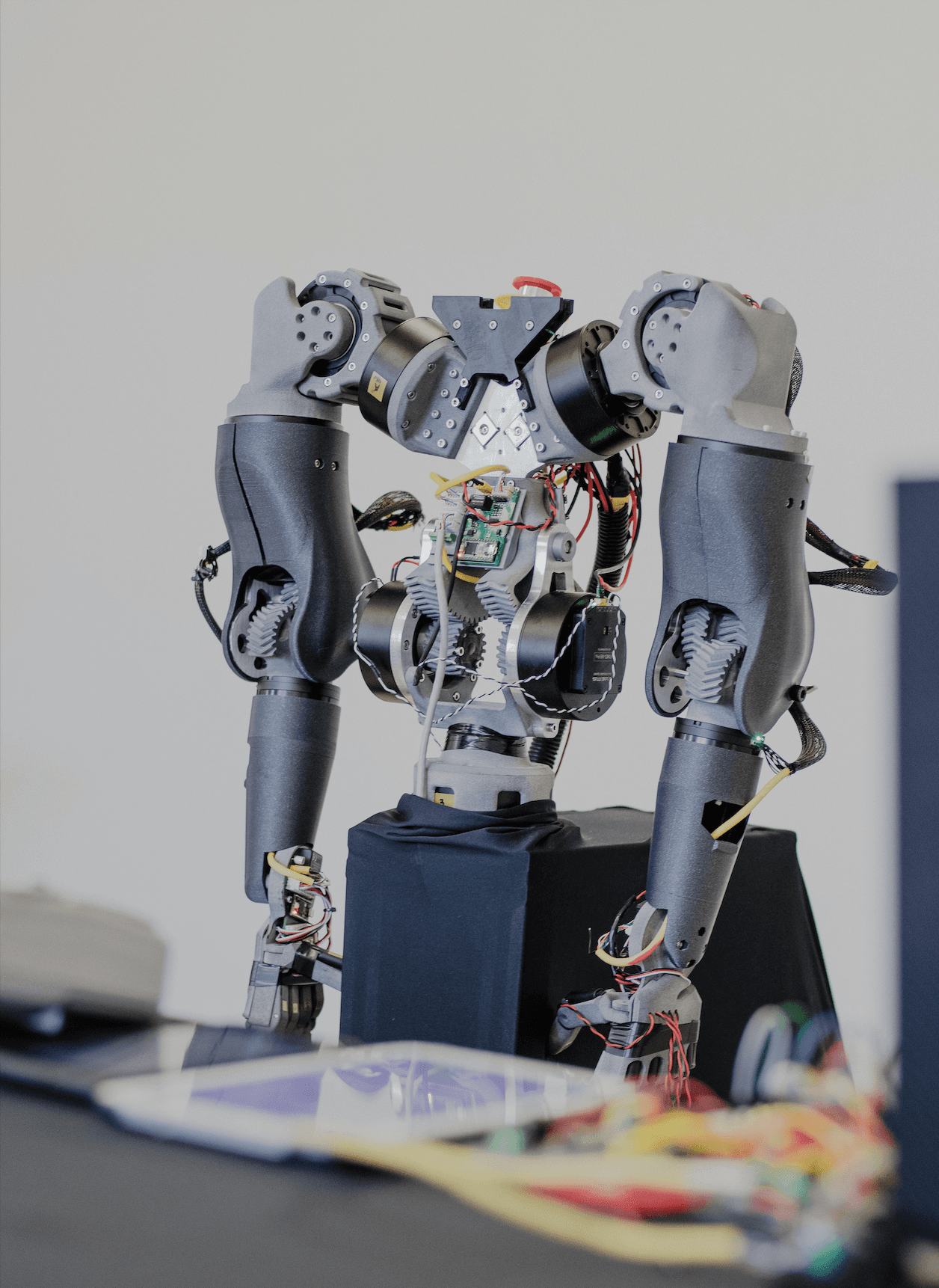

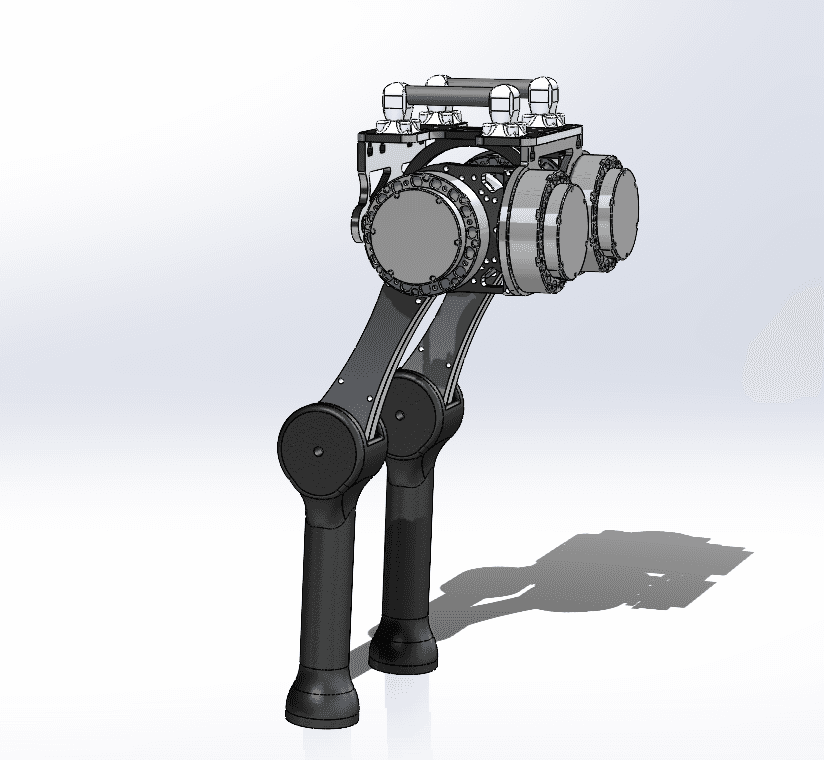

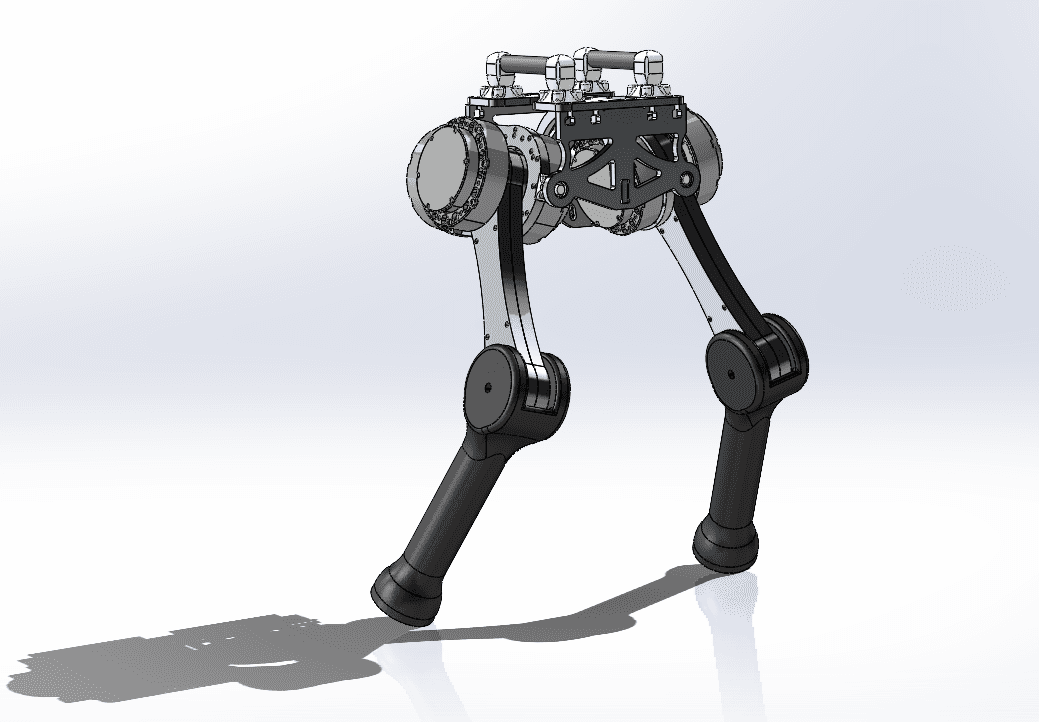

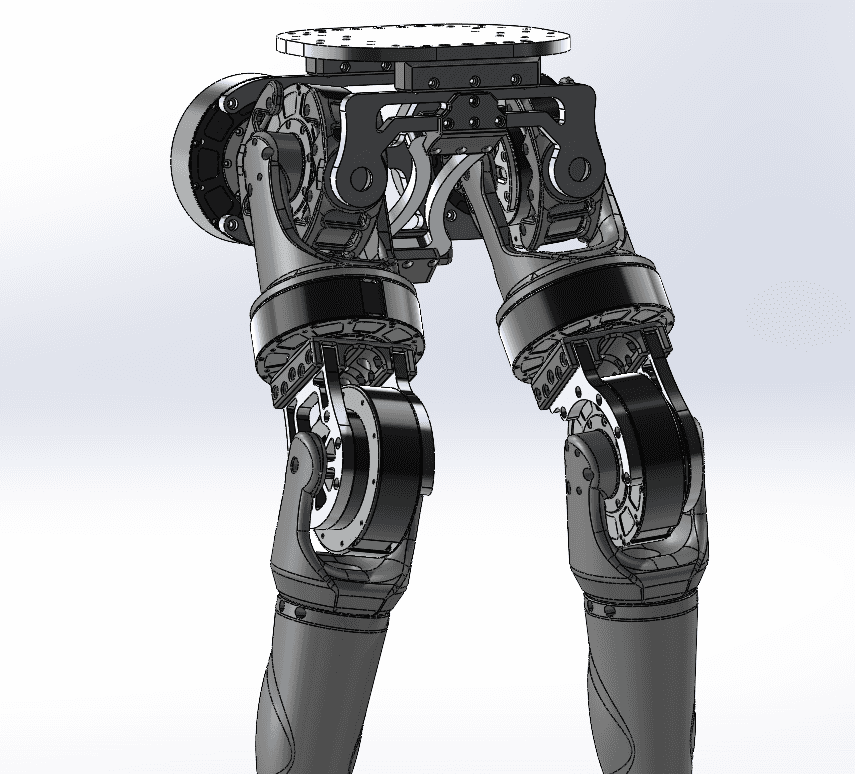

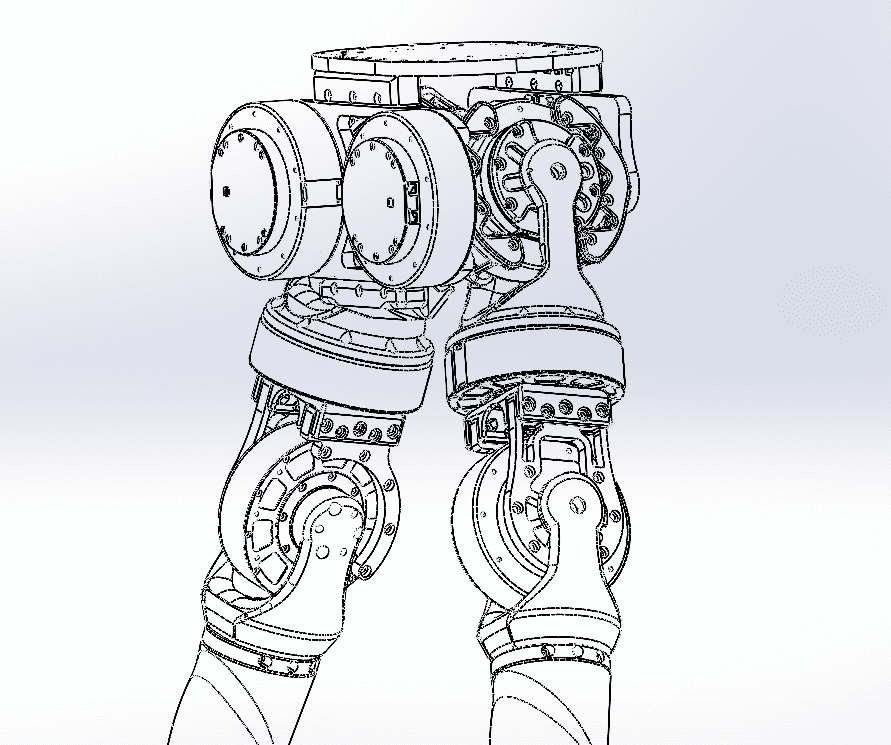

Robotic legs

I designed a bipedal robot (6-DOF) to test control and locomotion algorithms, inspired by MIT’s Little Hermes, along with anthropomorphic robot legs with eight degrees of freedom built for a 1.4-meter humanoid, this offer flexibility and control in each limb. The smaller bipedal model is top-weighted with lightweight limbs, perfect for testing inverted pendulum algorithms to improve stability. The anthropomorphic legs are ready for integration into larger robots, advancing bipedal control across different scales and applications.

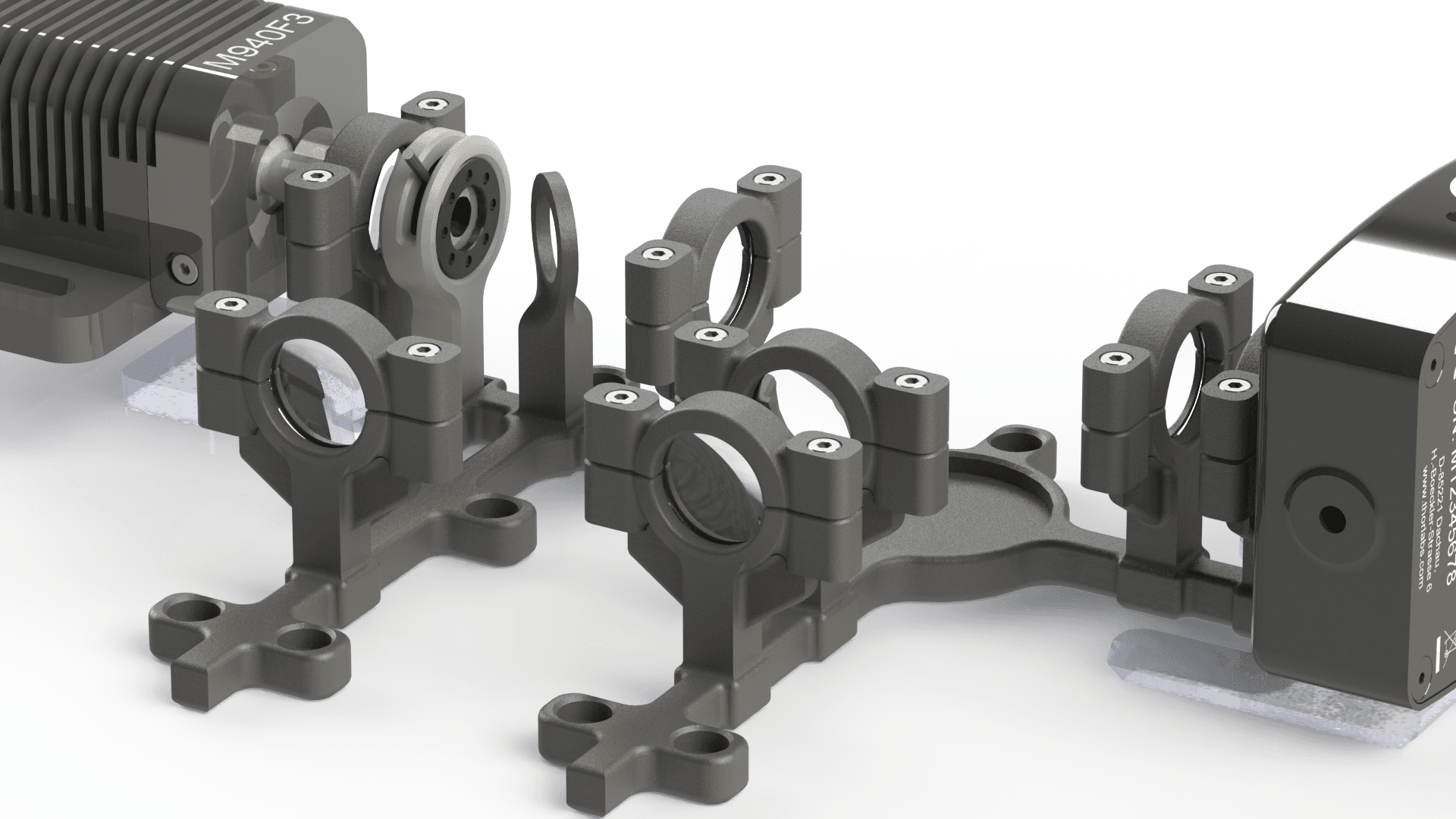

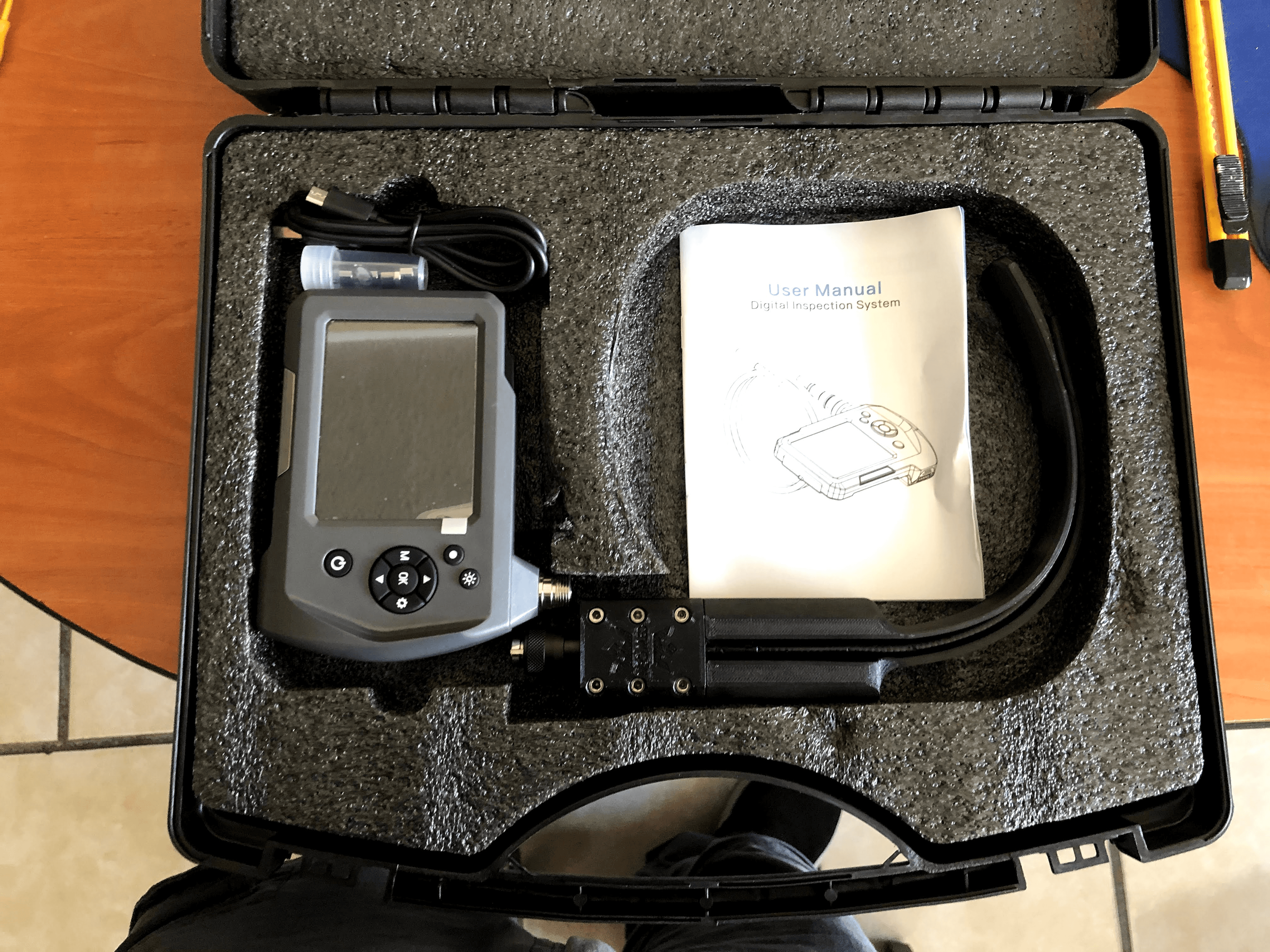

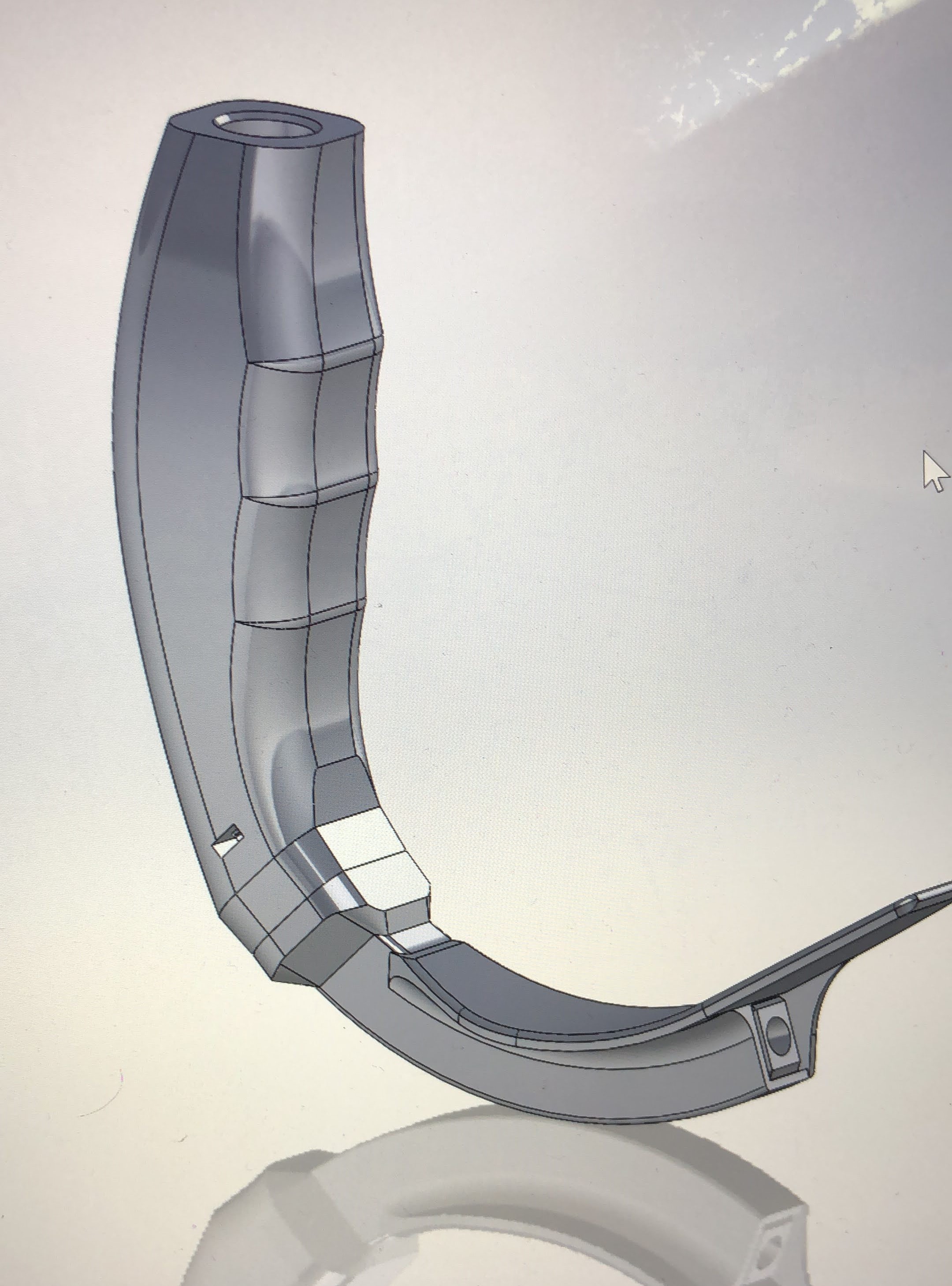

Digital 3D Printed Laryngoscope

During the COVID-19 pandemic, a doctor approached me with a request to design an affordable laryngoscope with a camera and screen to help doctors intubate patients. Existing devices were too expensive, so, with his guidance, I developed a custom 3D-printed solution to make this technology more accessible. I also created additional tools to guide intubation hoses, making the process easier. We successfully produced and distributed several units across Mexico, providing essential medical tools during a critical time.

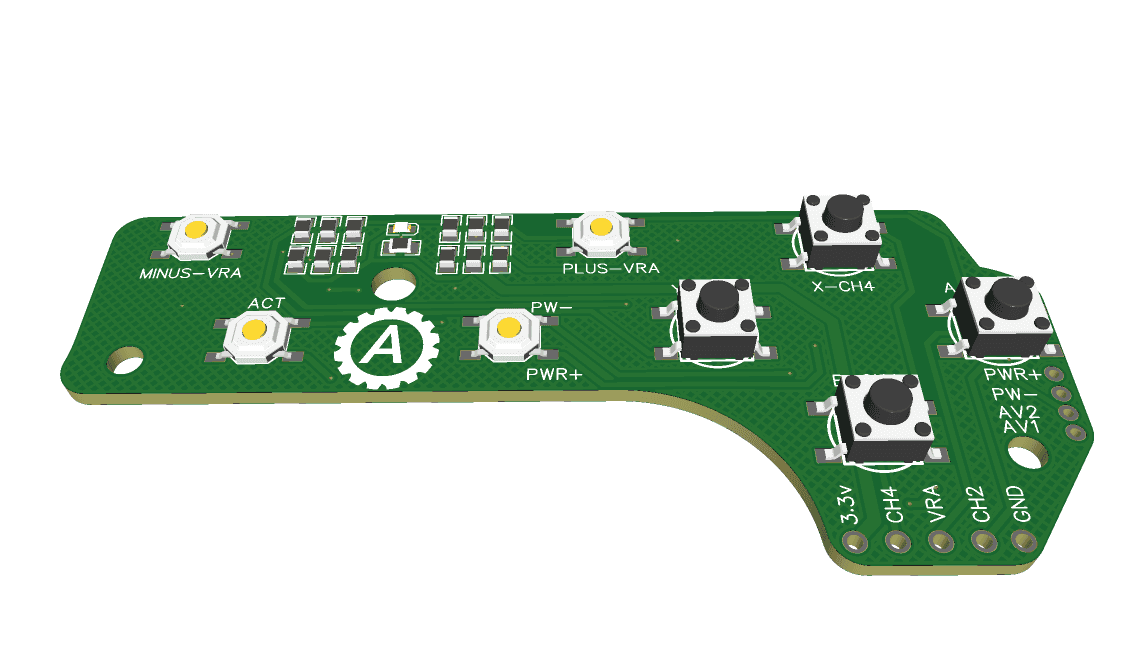

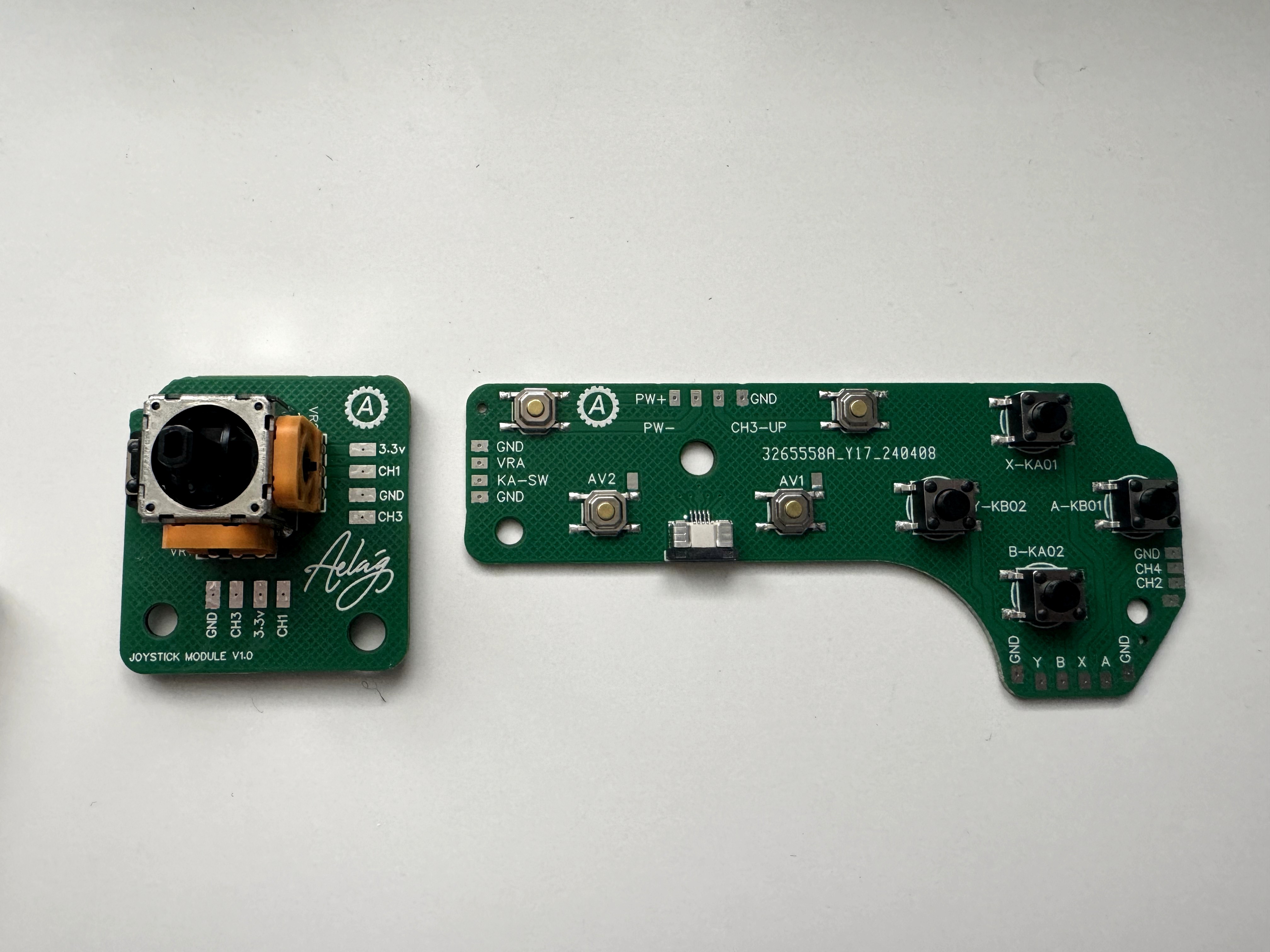

RF Pro Controller

I designed a custom radio frequency controller to improve the ergonomics and usability of traditional radio controls. Using a Nintendo Switch controller shell for comfort, I created a custom PCB to fit inside seamlessly and connected it to a radio frequency module for direct communication with my robot. This compact, ergonomic controller has greatly enhanced my control experience, incorporating electronic design as well as PCB manufacturing.

Vision Aid Wearable

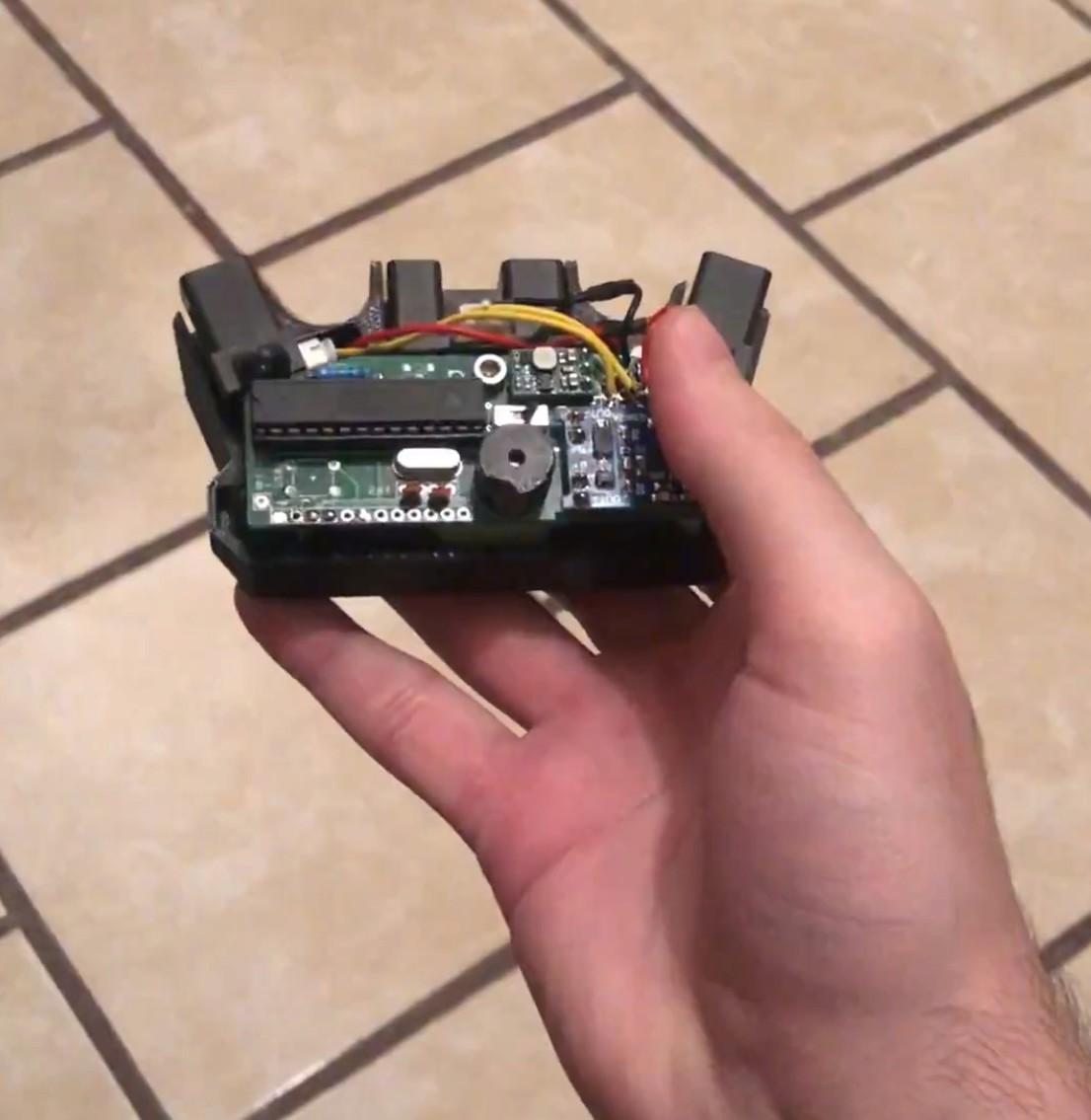

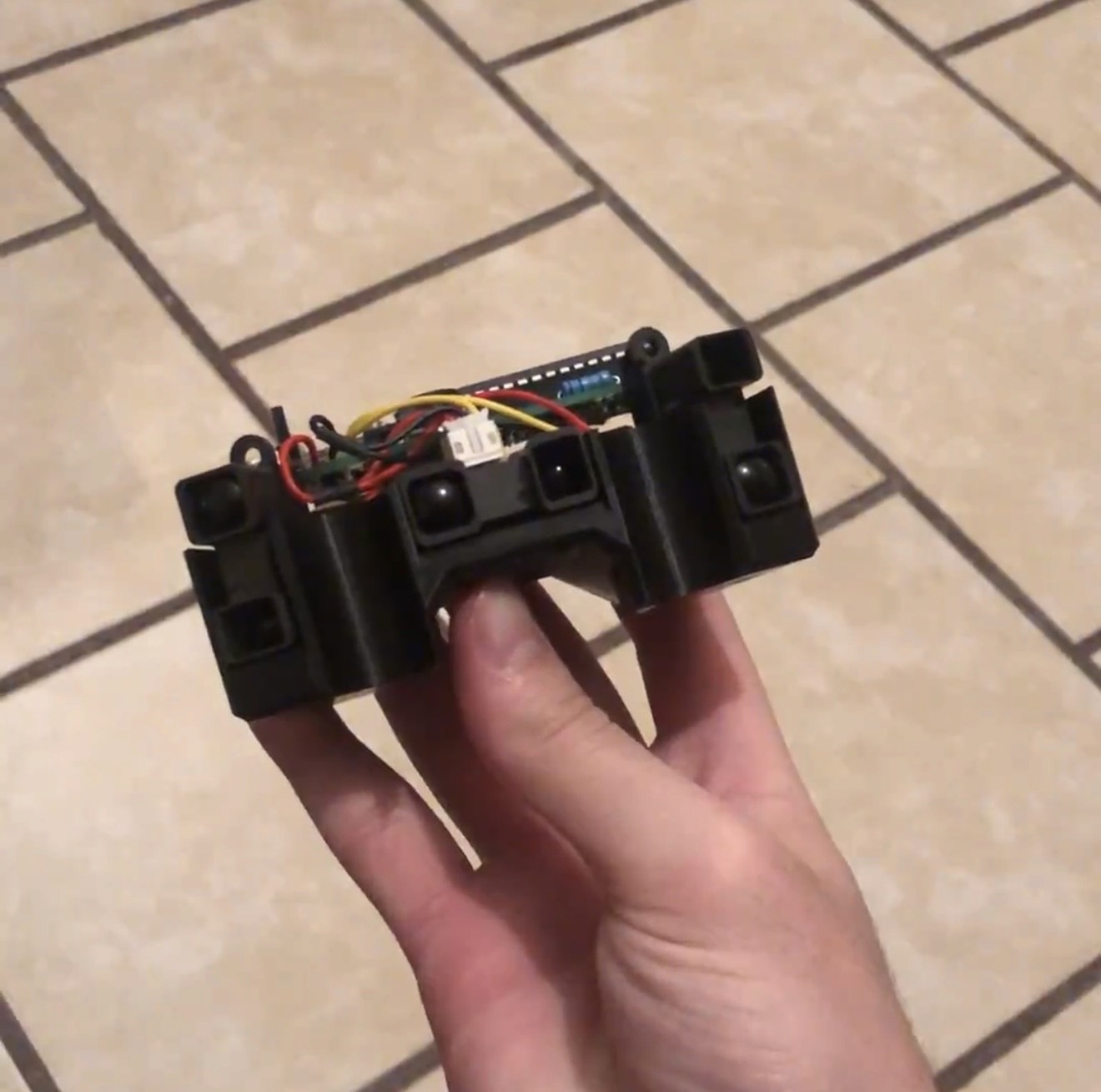

A wearable device was developed to assist visually impaired individuals in detecting obstacles. Designed as a necklace, it features a custom PCB with infrared sensors, a battery, and a charging module. The sensors detect objects at varying distances and emit beeps that intensify as the user approaches an obstacle, providing spatial awareness similar to vehicle reverse sensors. As an early prototype, the device demonstrated feasibility. Future iterations aim to reduce size by incorporating compact sensors, a pocket-sized battery, and directional audio for more discreet alerts.

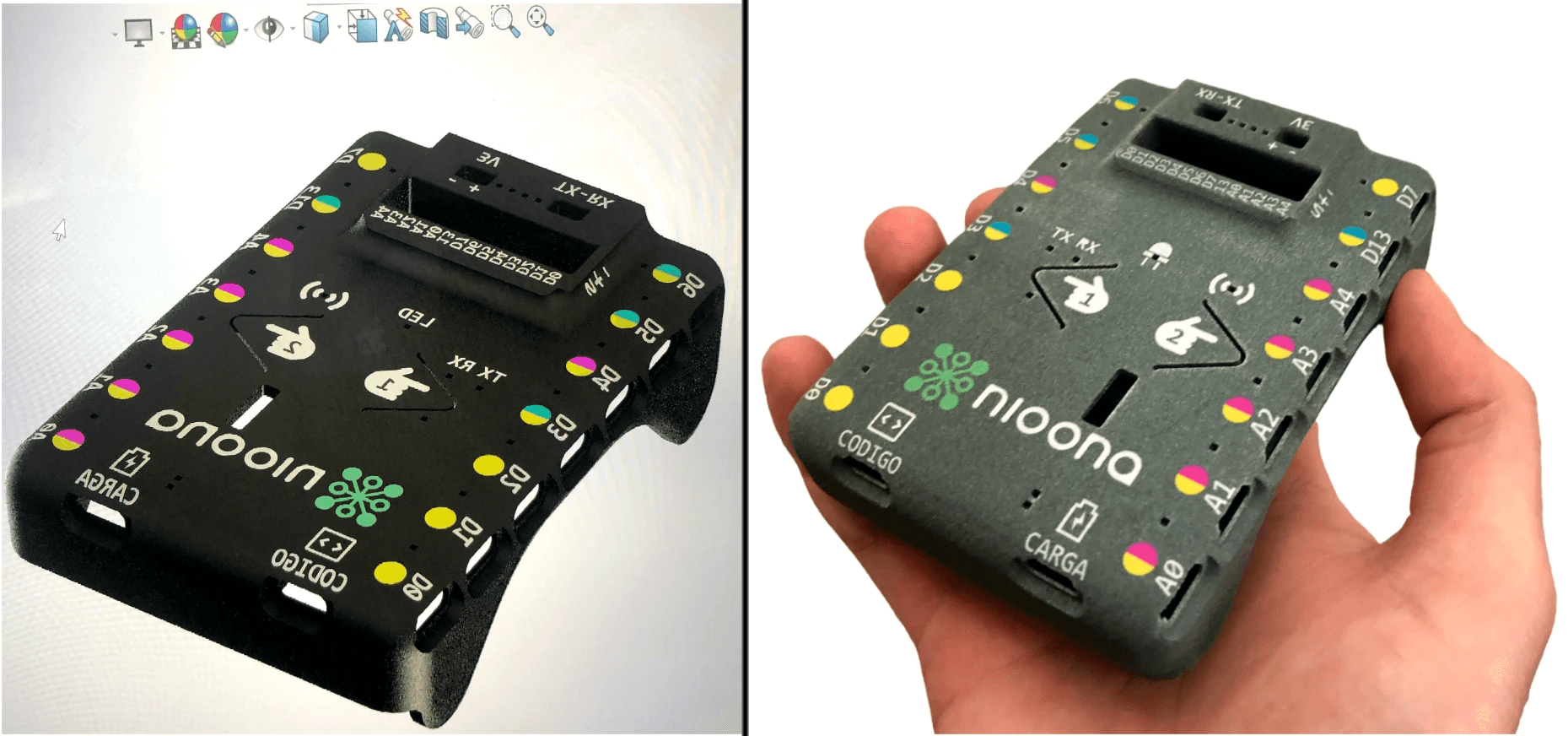

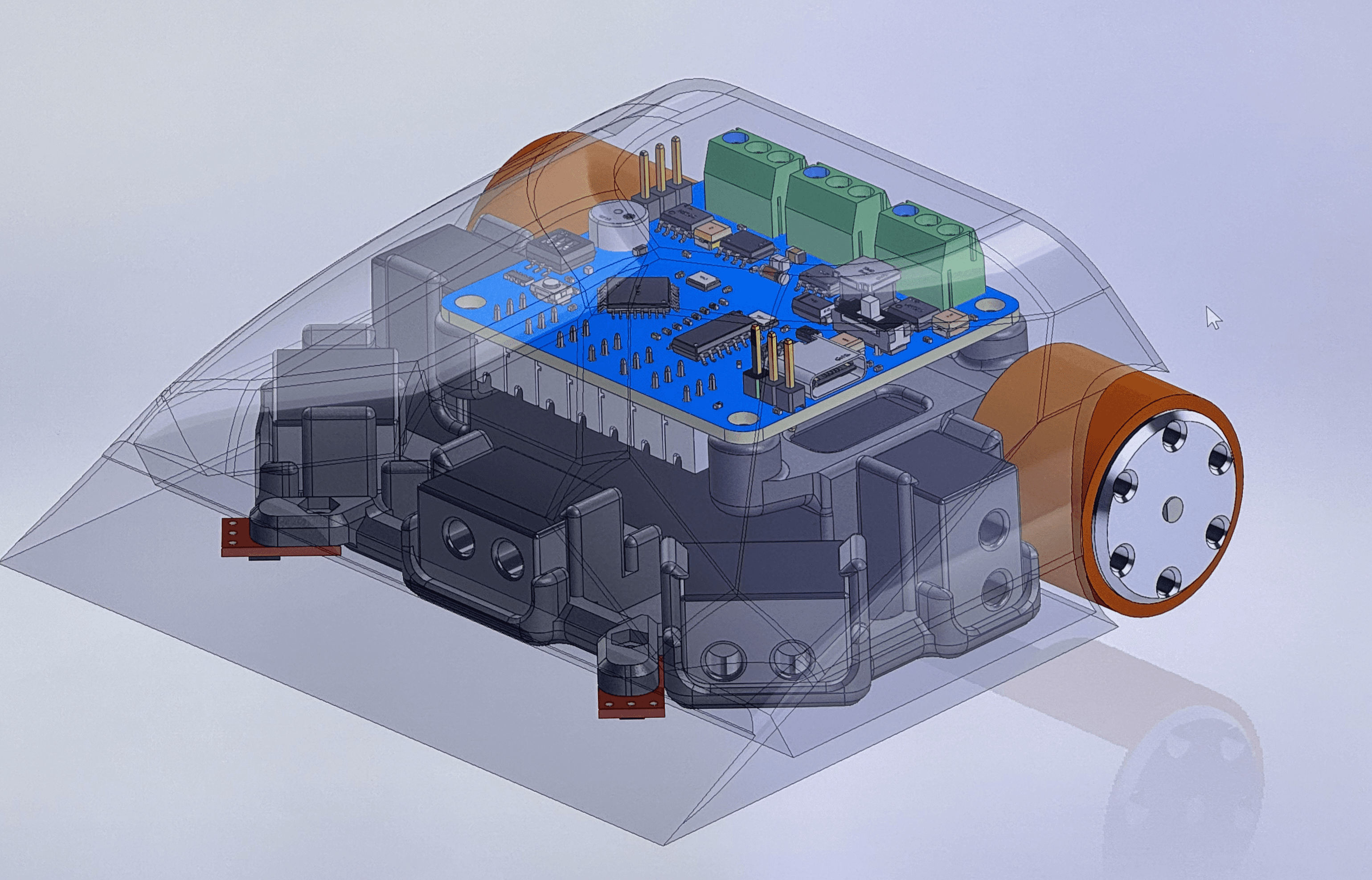

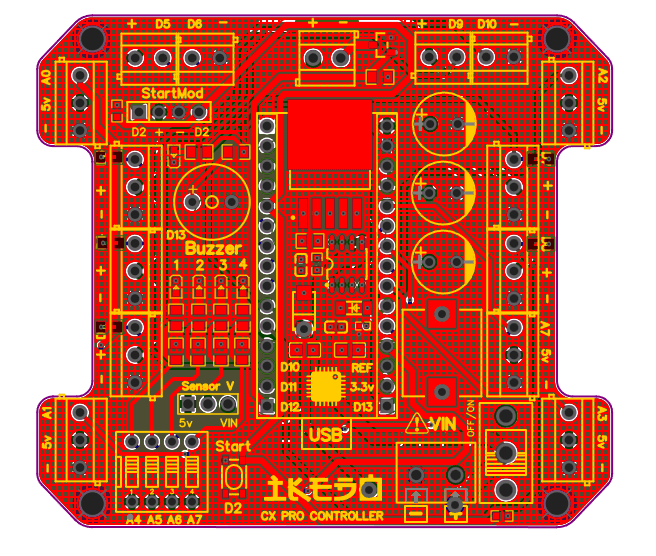

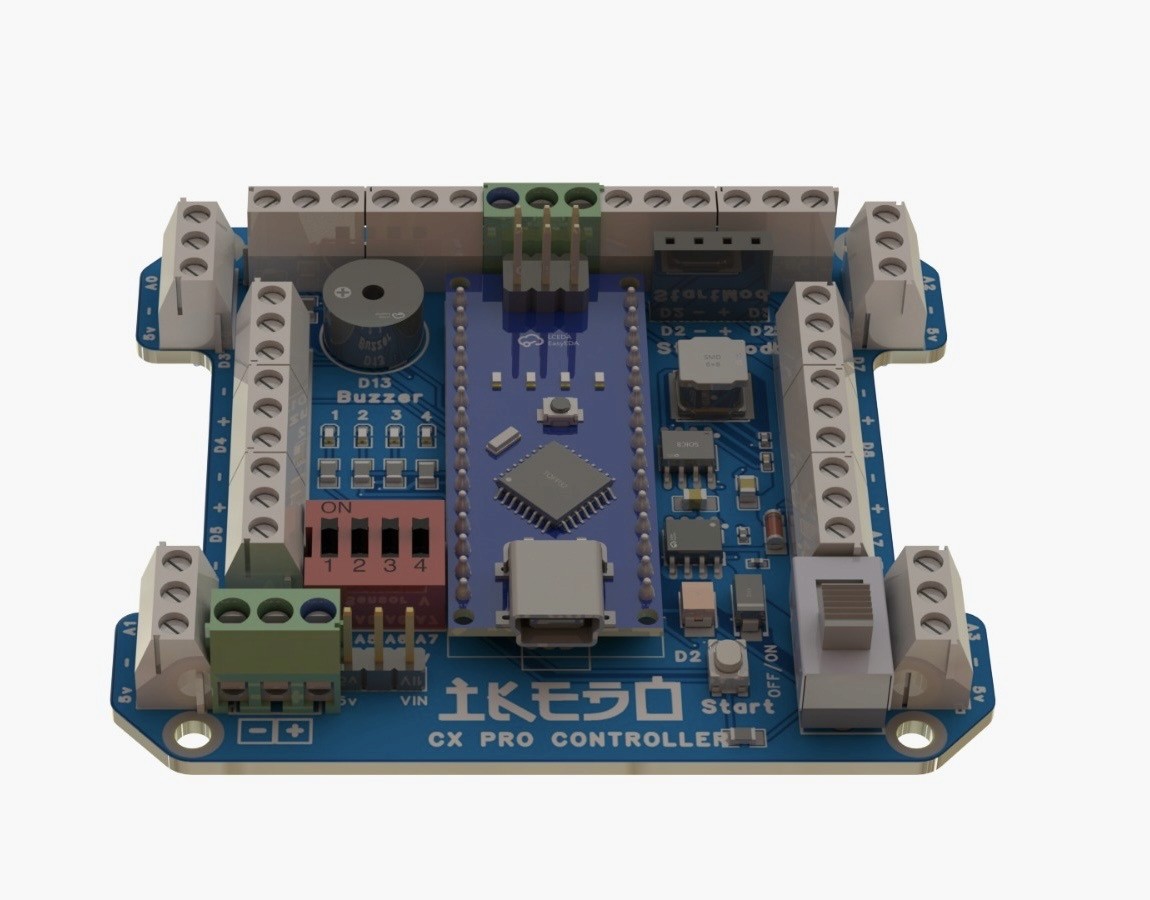

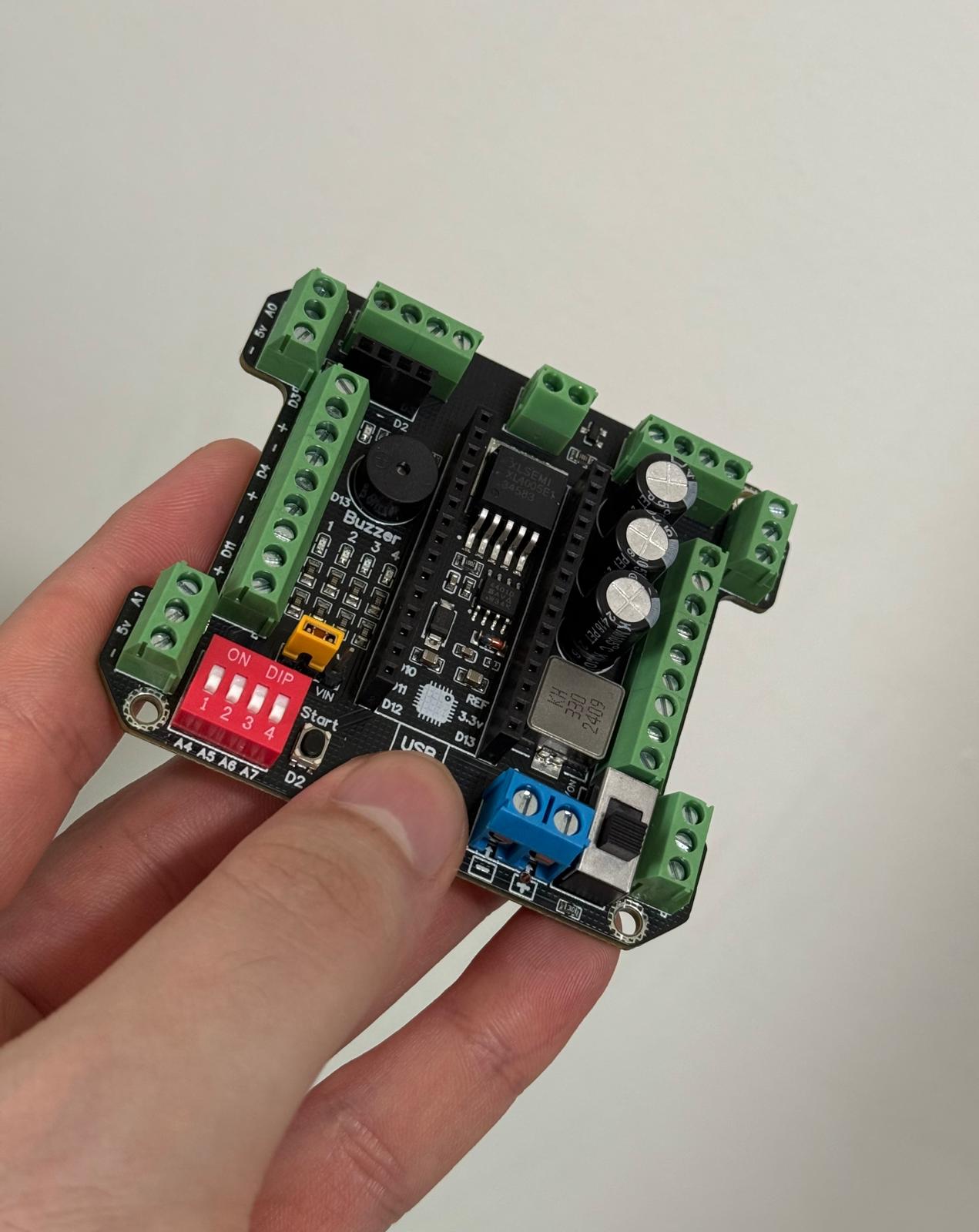

Microcontroller Shell for Autonomous Sumo

I designed a custom Arduino-based development board specifically for Robot Sumo applications, commissioned by a team in Malaysia and now widely used in their robots. This board includes a voltage regulation system that steps down from 24 volts to 5 volts, powering sensors and the microcontroller. It’s equipped with essential inputs and outputs for autonomous functions like routine selection and starter module integration. This project involved extensive electronics and PCB design, resulting in a reliable board tailored to competitive use.